Use our Concrete Block Calculator before you lay the first stone if you’re planning to create a concrete block wall. You may use it to determine how many cinder blocks are necessary for a certain wall size, calculate the amount of mortar required, and estimate the cost of the materials required for your project based on the average cost of it. Enter your wall measurements and block size to see how many concrete blocks and bags of mortar you’ll need for your project.

Then, to generate an approximate material price estimate, add the block price. People often mix cement and concrete, we have a calculator that will help you to understand these two. Be sure to check out our Cement Calculator, but also a Sand Calculator to calculate how much sand you need, or to estimate sand price.

Take a look other related calculators, such as:

What are Concrete Blocks?

We use concrete blocks to construct walls as a building material. It’s also known as a concrete masonry unit (CMU). It is one of the various precast concrete building components. The word “precast” refers to how the blocks are made and hardened before being delivered to the project site. Most blocks feature one or more hollow chambers, and the sides might be smooth or patterned. To build the appropriate length and height of the wall, they are piled one at a time and held together using new concrete mortar.

The Romans utilized concrete mortar to bind sculpted stones together to construct structures as early as 200 B.C. Small blocks of precast concrete were employed as a construction material in the region around present-day Naples, Italy, during the reign of the Roman emperor Caligula, from 37 to 41 a.d.

After the fall of the Roman Empire in the fifth century, most of the concrete technology established by the Romans was lost. Joseph Aspdin, an English stonemason, created portland cement in 1824, now the most important component of contemporary concrete.

Harmon S. Palmer of the United States created the first hollow concrete block in 1890. Palmer patented the idea in 1900 after ten years of experimentation. Palmer’s blocks were 8 in (20.3 cm) by 10 in (25.4 cm) by 30 in (76.2 cm) and had to be carried into place with a tiny crane because they were so heavy. Nevertheless, in 1905, an estimated 1,500 businesses in the United States were producing concrete blocks.

Concrete Block Dimensions

Concrete blocks, like bricks, have real and nominal dimensions. A nominal dimension is the actual dimension plus the width of the mortar joint. The average mortar junction is 3/8 inch wide. The nominal dimension is usable within the four dimensions. Other building materials adhere to a grid.

Concrete Block Sizes

They are available in a wide range of sizes. Their depth, or the thickness of the wall they form, distinguishes them. A 6″ block, for example, is nominally 6″ deep, whereas a 10″ one is nominally 10″ deep.

Half-size blocks are also available, avoiding the need to cut blocks in the field at corners or the ends of walls. To save waste and effort due to cut blocks, the architect should always design structures utilizing nominal measurements to the nearest half-block size.

Difference Between Concrete and Cement

Many individuals mistakenly assume that concrete and cement are the same things. As a result, you may hear someone say cement when they mean concrete and vice versa. Concrete and cement are, in fact, closely related yet vastly distinct materials. A bonding agent is cement. More importantly, cement is the bonding agent utilized in concrete. That’s true.

Cement isn’t concrete; it’s only a component of it. When mixed with water, cement forms a paste that holds all of these elements together. We can use cement for more things than concrete. It’s employed in plastering mortar and masonry grout. On the other hand, cement is a binding substance that is never employed independently.

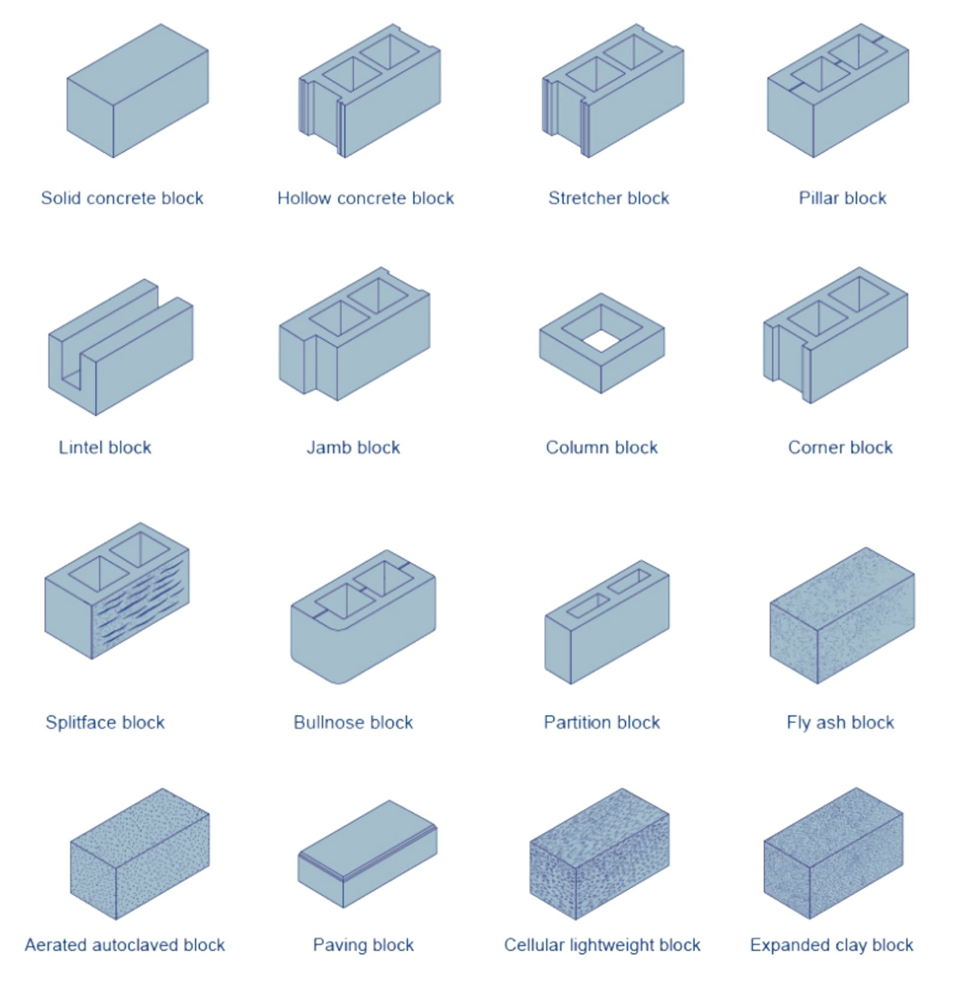

Concrete Block Types

In this calculator, we will provide you with some types of concrete blocks. We have two categories, based on their structure, shape, size, and production procedures.

- Solid blocks

- Hollow blocks

Solid concrete blocks

Solid concrete blocks, which are massive and made from thick aggregate, are frequently employed. They are extremely robust and give excellent structural stability. Solid blocks are preferred for big masonry projects, such as load-bearing walls.

In comparison to bricks, they come in larger sizes. As a result, concrete masonry takes less time to construct than brick masonry.

Hollow concrete blocks

The void area of hollow concrete blocks is larger than 25% of the total area. The solid area of hollow bricks should be greater than 50%. The hollow section might be separated into numerous components depending on our needs.

Lightweight aggregates are used to make them. They’re lightweight and simple to put together. So here are some types of the hollow concrete blocks:

- Stretcher block. Stretcher blocks are hollow concrete blocks that are commonly used in construction. They’re placed with their length parallel to the wall’s face.

- Corner block. The ends, which might be window or door apertures, are placed so that their plane end is visible from the outside and the other end is secured with the stretcher block.

- Pillar block. The double corner block is another name for pillar block. So we can use these blocks for piers and pillars.

- Jamb block. Jamb blocks are particularly important for providing room for the window casing parts when installing double hung windows.

- Partition block. We can use them to construct partition walls. This is because partition blocks are taller than they are wide. In the case of partition blocks, the hollow section is separated into two to three components.

- Lintel block. The purpose of a lintel block or beam block is to provide a beam or lintel beam. Lintel beams are typically installed on the upper section of doors and windows to support the load from above.

- Frogged brick block. Frogged brick block has a frog on top, as well as a header and stretcher, similar to a frogged brick. This frog will aid the block in retaining mortar and forming a solid link with the top lying block.

- Bull nose block. Bull nose bricks are favored when we desire rounded edges at corners.

Formula

The first step to knowing the number of blocks required is to determine the size of your wall. To do so, follow the next equation:

Wall size = {Wall Height \times Wall Width }Concrete Block Cost

Simply multiply the quantity of cinder blocks by the price of a single block to calculate your costs:

Concrete Block Costs = {Price Per Block \times Number Of Blocks }Total Number of Blocks Needed

To figure out how many blocks there are, divide the wall’s entire area by the area of a single block:

Number Of Blocks Needed = \frac {Wall Area} {Block Area}Block Area={Block Height \times Block Width } Concrete Block Calculator – How to Use?

Our calculator is easy to use and understand. Simply follow these steps to estimate all of your project’s requirements:

1. Input the width and height of the concrete block wall you’re constructing. They’re required for calculating the square footage of a wall.

2. Choose whether you want to use a predefined block size or create your own:

- The preconfigured block sizes correspond to the six most prevalent varieties found in the United States. If you want to know what they are in metric, feel free to use our length converter. Now you have to select the appropriate size.

- If you choose custom size, you must enter the height and breadth of a single concrete block into the calculator. To minimize misunderstanding, an example of a wall segment will emerge to demonstrate exactly which proportions are required.

- The total quantity of concrete blocks required for your project will be shown in both circumstances.

3. Calculate the cost of concrete blocks by entering the price of a single block.

4. Take a look at the field for mortar estimate. For example, to join 100 concrete blocks, it takes three normal mortar bags on average. Wow, this calculator is really amazing!

Concrete Block Calculator – Example

Assume your wall will be 10 feet tall and 50 feet long. It will cover 500 square feet with these sizes.

10 \times 50 = 500A single 16″ × 8″ concrete block has a surface area of 128 square inches, therefore you’ll need 563 concrete blocks.

00 \; ft^2 \div 128 \; in^2 = 72.000 \; in^2 \div 128 \; in^2= 562.5You will pay $844.5 if one cinder block costs $1.5.

563 \times \$ 1.5 = \$ 844.5In terms of the mortar bags, multiplying 563 by 33.3 yields 16.9. Because you can only buy complete bags, you’ll need 17 regular bags of mortar for this project. Or just simply enter the values in our calculator, and we will do the rest of the work for you.

Besides this, our other concrete related posts may help you with your projects, such as Concrete Weight, Conrete Column and Concrete Estimator Tube.

FAQ:

How to calculate concrete blocks needed?

Substitute the numbers in the equation square feet of block = (length x height) / 144 for the length and height of the block in inches. A normal cement block, for example, measures 16 by 8 inches and covers 0.89 square feet (16 x 8) / 144 = 0.89.

How much does a concrete block weigh?

The weight should be around 35 pounds (16 kg). In the United States, the usual size is 8-inch by 8-inch by 16-inch. Cinder blocks are a versatile building material that may be utilized in a variety of projects.

How many standard blocks are in a square meter?

Ten blocks per square metre are required for a single block wall.

How many blocks do I need to build a 2 bedroom house?

After you’ve determined the square footage of both your wall and your block, all you have to do now is divide the wall square footage by the block square footage to get the number of blocks you’ll need. For example, divide the square wall footage by 0.89 to get the number of blocks you’ll need if you’re using a normal 16′′ x 8′′ x 8′′ block.

How many blocks are in a pallet?

There are 72 blocks in a pallet.