The Spindle Speed Calculator may help you determine the speed and feed rates you need for any lathe or milling operation. Furthermore, turning, facing, milling, finishing, knurling, grooving, and other material removal procedures are carried out on these heavy-duty machines, which are the backbone of the industrial sector.

To preserve dimensional accuracy of the workpiece and completed product, they must use the appropriate spindle speeds and feeding rates when performing stated processes. This article aims to explain what it is and how to calculate it, as well as how to determine feed rate.

You’ll be able to compute speed for milling and lathe operations once you’ve completed the example exercise. While you are here make sure to check more calculators from the construction category, such as Roof Pitch Calculator, Concrete Calculator, etc.

Take a look other related calculators, such as:

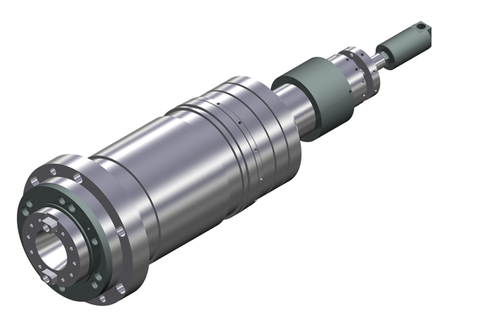

What is a Spindle?

A spindle is a revolving axis of a device that commonly contains a shaft at its centre in appliance tools. The shaft is termed a spindle, but on the shop floor, the term is frequently used to refer to the full rotating unit, which includes the shaft and its bearings and everything else attached to it (chuck).

A machine tool, such as the headstock and tailstock spindles on a bench lathe may contain several spindles. The largest spindle is generally the primary one. When “the spindle” is spoken without a qualifier, it refers to the primary one. Some machine tools with a group of four, six, or even more main spindles are designed for high-volume mass manufacturing, which we call multispindle machines.

Multispindle machines include gang drills and numerous screw machines, for example. Although a bench lathe contains more than one spindle (including the tailstock), it is not a multispindle device; it only has one main spindle.

Spindle Speed and Feed Rate – What are they?

The spindle speed is defined as the rotating speed of the machine’s spindle. Moreover, the workpiece is attached to the chuck, which is attached to the spindle of a lathe or CNC machine. Aside from the lathe, the spindle carries drill bits in the chuck, grinding wheels, and milling or shaping tools.

The tool would be subjected to normal wear and tear due to its contact with the workpiece throughout the material removal operation. The speed influences the surface finish of the workpiece and the cut (cutting) tool’s lifespan. We use it for machining wood, metal and other materials.

The feed rate is defined as the length of material supplied into the tool per unit time.

Spindle Speed Formula

The spindle speed formula gives the spindle speed N_s, in rpm, for a machine working at cut (cutting) speed V, in m/min:

N_s = \dfrac{V\cdot1000}{\pi \cdot D}where D is the workpiece’s diameter in millimetres, we use the above equation to compute speed while milling or other material removal activities are performed.

Feed Rate Formula

The feed rate F_r, in m/min, for machining processes is similarly affected by spindle speed. The feed rate is defined as the length of material supplied into the tool per unit time.

The following equation gives the feed rate calculation formula for an appliance with Z teeth:

F_r = N_s \cdot F_t \cdot Z

Where F_r is the feed per tooth in mm.

Feed Per Tooth Formula

Feed per tooth is a milling word denoted by F_z and measured in millimetres or inches. It denotes the chip thickness removed from the material by each milling cutter tooth as it passes through it. Milling cutter vendors provide a suggested chip load.

Furthermore, the Table Feed must be obtained from the CNC software by the CNC device. The Feed per Tooth is an auxiliary number utilized in the computation chain to calculate the Table Feed from the chip load. The following equation gives the feed per tooth calculation formula:

F_z=\dfrac{vf}{z \cdot n} \dfrac{mm}{t}where vf is Table Feed in mm per min, n is spindle speed in min^{-1} and z represents the number of flutes.

Spindle Speed Calculator – How to Use?

When you find yourself in need to calculate Spindle Speed in our calculator, you need to follow those steps:

- Enter the diameter of the part, D = x mm.

- Fill in the cut speed, V = x m/min.

- Calculation is done using the spindle speed formula:

N_s= \dfrac{V \cdot 1000}{\pi \cdot D}The preceding paragraph illustrates how to determine the milling feed rate. To utilize the feed rate calculation formula, follow these steps:

- Enter the number of teeth, Z = x.

- Insert the feed per tooth, Ft = x mm.

- The feed rate is: F_r = N_s \cdot F_t \cdot Z

Spindle Speed Calculator – Example

Determine the spindle speed required to mill a steel workpiece with a diameter of 30 mm. Assume that the cutting speed V is 7 m/min. Determine the feed rate for a single tooth with a feed per tooth of 12 mm as well.

To determine spindle speed, use the following steps:

- Enter the diameter of the part, D = 30 mm.

- Fill in the cutting speed, V = 7 m/min.

- Calculation is done using the spindle speed formula:

N_s= \dfrac{V \cdot 1000}{\pi \cdot D}N_s = \dfrac{7 \cdot 1000}{\pi \cdot 30} = 74.27 rpmThe preceding paragraph illustrates how to determine the milling feed rate. To utilize the feed rate calculation formula, follow these steps:

- Enter the number of teeth, Z = 2.

- Insert the feed per tooth, Ft = 12 mm.

- The feed rate is:

F_r = N_s \cdot F_t \cdot Z

F_r = 74.27 \cdot 0.012 \cdot 2 = 1.7825

FAQ

How do you calculate spindle speed?

To compute spindle speed, follow these steps:

First, multiply the cutting speed by 1000.

Then, divide the result by the circumference of the workpiece/tool.

How do I choose a spindle?

Select a CNC spindle with the RPM, power, and cooling required for your material. For example, a spindle with 24,000 RPM and 1kW power is enough for wood and aluminium. For steel, RPMs between 15,000 and 18000 and a power of 5.6 kW are sufficient for tool sizes up to 12 mm.

What should spindle speed be?

The spindle speed is the rotational frequency of it, measured in revolutions per minute (RPM). Moreover, working backwards from the required surface speed (sfm or m/min) and including the diameter yields the ideal speed (of workpiece or cutter).

What is the difference between cutting speed and spindle speed?

Machinists refer to the angular velocity of the workpiece (rev/min) as the “spindle speed.” Machinists refer to its tangential linear equivalent at the workpiece surface (m/min or sfm) as the “cutting speed,” “surface speed,” or simply “speed.”

What happens if the spindle speed is too high?

Too fast: Excessive spindle speed generates heat, which softens and dulls the tool quicker.

How do you calculate cutting speed?

Tangential velocity on the tool or workpiece’s surface at the cutting interface. The cutting speed (sfm) formula is tool diameter 5 0.26 5 speed (rpm).

What are the parts of a spindle?

The machining parts share certain commonalities:

Shaft.

Whorl.

Cop.

Supported spindles.

Bottom whorl drop spindles.

Top whorl drop spindles.